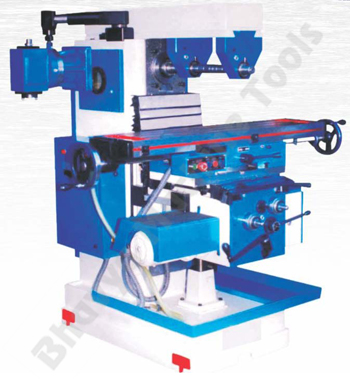

A milling machine is a tool that is basically used to shape or cut solid metals by removing the excess material in order to form a finished product. These are mostly utilized in the metalworking industry to perform a wide range of complex cutting operations; such as keyway and slot cutting, drilling, diesinking, threading, carving, milling, rebating, planing, routing, and much more.

A milling machine is a tool that is basically used to shape or cut solid metals by removing the excess material in order to form a finished product. These are mostly utilized in the metalworking industry to perform a wide range of complex cutting operations; such as keyway and slot cutting, drilling, diesinking, threading, carving, milling, rebating, planing, routing, and much more.

Versatility is the primary reason to use milling machines for shaping metals. These are powerful tools with the capability of cutting a wide range of metals from aluminum to stainless steel. Nowadays, a variety of technologically advanced are manufactured to satisfy the growing needs of several industrial sectors.

Milling equipments are built with different specifications and each is named based on a particular function. All milling tools essentially serve the basic purpose of cutting and shaping metals. However, each is categorized into different groups based on the various standard specifications. These multi purpose machines can simultaneously carry out multiple tasks such as milling, cutting, drilling etc.

Milling tools are available in various sizes and can have a horizontal or a vertical orientation. In a horizontal the spindle faces horizontally, whereas a vertical has a spindle axis that faces vertically. It can be manually operated or mechanically automated. A computer numerical control or CNC milling tool is digitally operated, and helps to avoid accidents and save labor costs.

Milling tools are available in various sizes and can have a horizontal or a vertical orientation. In a horizontal the spindle faces horizontally, whereas a vertical has a spindle axis that faces vertically. It can be manually operated or mechanically automated. A computer numerical control or CNC milling tool is digitally operated, and helps to avoid accidents and save labor costs.

Every type has a different working speed to accurately cut the metals. It can be adjusted to move at a slow or fast speed as per the material being cut and according to specific requirements. Soft materials are usually shaped at higher speeds whereas hard materials are normally milled at a slow speed. Moreover, small quantities of a hard object can be cut at the same time.

A typical operation involves feeding the material over a device called a milling cutter. The ground slides, lead screws and teeth of the cutters; carve the work piece into precise and desired shapes. These popular machines can mill, thread, grind and do much more. A milling machine can even drill holes straight down like a drill press. The work piece can also be kept at the side of the tool in order to shape its edges.

There are numerous types of it, each with varying functions based on standard requirements. They are normally termed based on the orientation of the spindle; number of axis present; type of control; size of the tool; its purpose; as well as the source of power. The common types of manual milling include; turret milling equipment also known as vertical ram mills; box or column mills; c-frame mills; planer style mills, knee-mill or the knee-and-column mill; horizontal mill, bed type mill, tracer controlled mill etc.

There are numerous types of it, each with varying functions based on standard requirements. They are normally termed based on the orientation of the spindle; number of axis present; type of control; size of the tool; its purpose; as well as the source of power. The common types of manual milling include; turret milling equipment also known as vertical ram mills; box or column mills; c-frame mills; planer style mills, knee-mill or the knee-and-column mill; horizontal mill, bed type mill, tracer controlled mill etc.

The main advantage of manual milling machines is that they are not very expensive. Hence, It is a perfect solution for performing different tasks related to shaping various metals.