Bhavya Machine Tools at AMTEX 2026: Pioneering the Global Industrial Evolution

The global manufacturing landscape is undergoing a seismic shift. As we navigate the year 2026, the demand for high-precision, automated and energy-efficient machinery has never been greater. At the heart of this industrial evolution stands Bhavya Machine Tools, a name synonymous with reliability and engineering prowess.

This July, the industry’s most influential players will converge at AMTEX 2026 (Asian Machine Tool Exhibition) and Bhavya Machine Tools is set to be a cornerstone of the event. Whether you are a domestic manufacturer from India or a global buyer from the Middle East, Europe, North America or Asia, this is your premier opportunity to witness the future of metalworking technology.

Email Us

Email Us

Event Logistics at a Glance

- Venue: India Expo Mart, Greater Noida, Delhi NCR, India

- Bhavya Machine Tools Stall: Hall No. 9 | Stall No. A-29

- Dates: 24th to 27th July, 2026

Read Our Article

The Machine Tools Industry in BahrainWhy AMTEX 2026 is the Global Manufacturing Epicenter?

AMTEX has long been recognized as the platform “where India buys manufacturing technology.” In 2026, the move to the India Expo Mart in Greater Noida is a strategic masterstroke. This world-class venue places the exhibition at the epicentre of India’s most vibrant industrial clusters – Noida, Gurugram, Faridabad and Ghaziabad.

For the international audience, Greater Noida offers seamless connectivity to the national capital and international airports, making it a convenient hub for decision-makers from the USA, Canada and Europe. AMTEX 2026 isn’t just a trade show; it is a convergence of AI-driven manufacturing, Industry 4.0 integration and sustainable engineering solutions.

Bhavya Machine Tools: A Legacy of Engineering Trust

With a legacy spanning over three decades, Bhavya Machine Tools has transitioned from a localized supplier to a global powerhouse. Headquartered in Ahmedabad, the company has built its reputation on a simple yet powerful philosophy: bridging the gap between emerging global technologies and the practical needs of the manufacturer.

By maintaining a massive inventory of ready-to-ship machines and a robust network of international branches – including a dedicated presence in the Middle East – Bhavya Machine Tools ensures that quality engineering is always within reach. Our participation in AMTEX 2026 is a testament to our commitment to empowering both small-scale units and massive OEM facilities with tools that drive profitability.

The Showcase: A Deep Dive into Bhavya Machine Tools’ Portfolio

At Stall A-29, visitors will experience a live gallery of industrial might. Bhavya’s portfolio for 2026 covers every facet of the metalworking spectrum.

Our Other Machine

All Geared Heavy Duty LatheThe Power of Precision: Metal Cutting & Machining

The backbone of any workshop is its cutting and machining capability. Bhavya’s 2026 lineup focuses on high-torque, low-vibration machines designed for 24/7 operation.

- Lathe Machines (Manual & Heavy Duty): From light-duty lathes for tool rooms to extra-heavy-duty models for large-scale industrial turning, these machines are built with hardened and ground bed ways to ensure long-term accuracy.

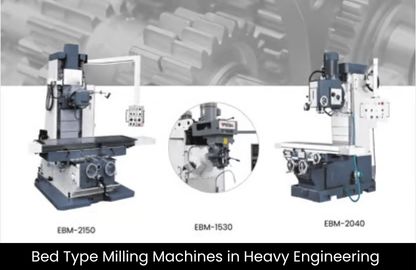

- Milling Machines: Featuring Vertical, Turret and Universal Milling configurations. These machines allow for complex multi-axis machining, essential for the aerospace and automotive sectors.

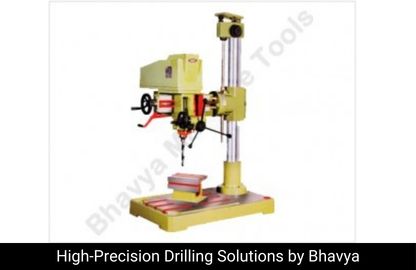

- Drilling Machines: The showcase includes Radial Drill Machines for large work pieces and Pillar Drill Machines for precision holes. The addition of Electric Tapping Machines reflects the industry’s shift toward high-speed, error-free threading.

- Shaping & Slotting Machines: Crucial for creating internal keyways and complex shapes, these machines offer the rigidity required for heavy-duty metal removal.

Metal Forming and Fabrication Excellence

As industries in Africa and Southeast Asia see a surge in infrastructure and construction, metal forming technology has become a high-priority investment.

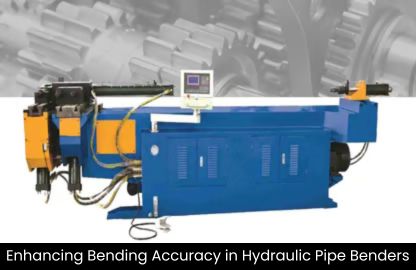

- Bending and Press Brake Machines: Bhavya’s range includes Hydraulic Press Brakes and NC Press Brake Machines, offering programmable precision for repetitive bending tasks.

- Shearing and Cutting: High-performance Hydraulic Shearing and Folding Machines ensure clean cuts and precise folds, minimizing material wastage – a key concern for modern sustainable manufacturing.

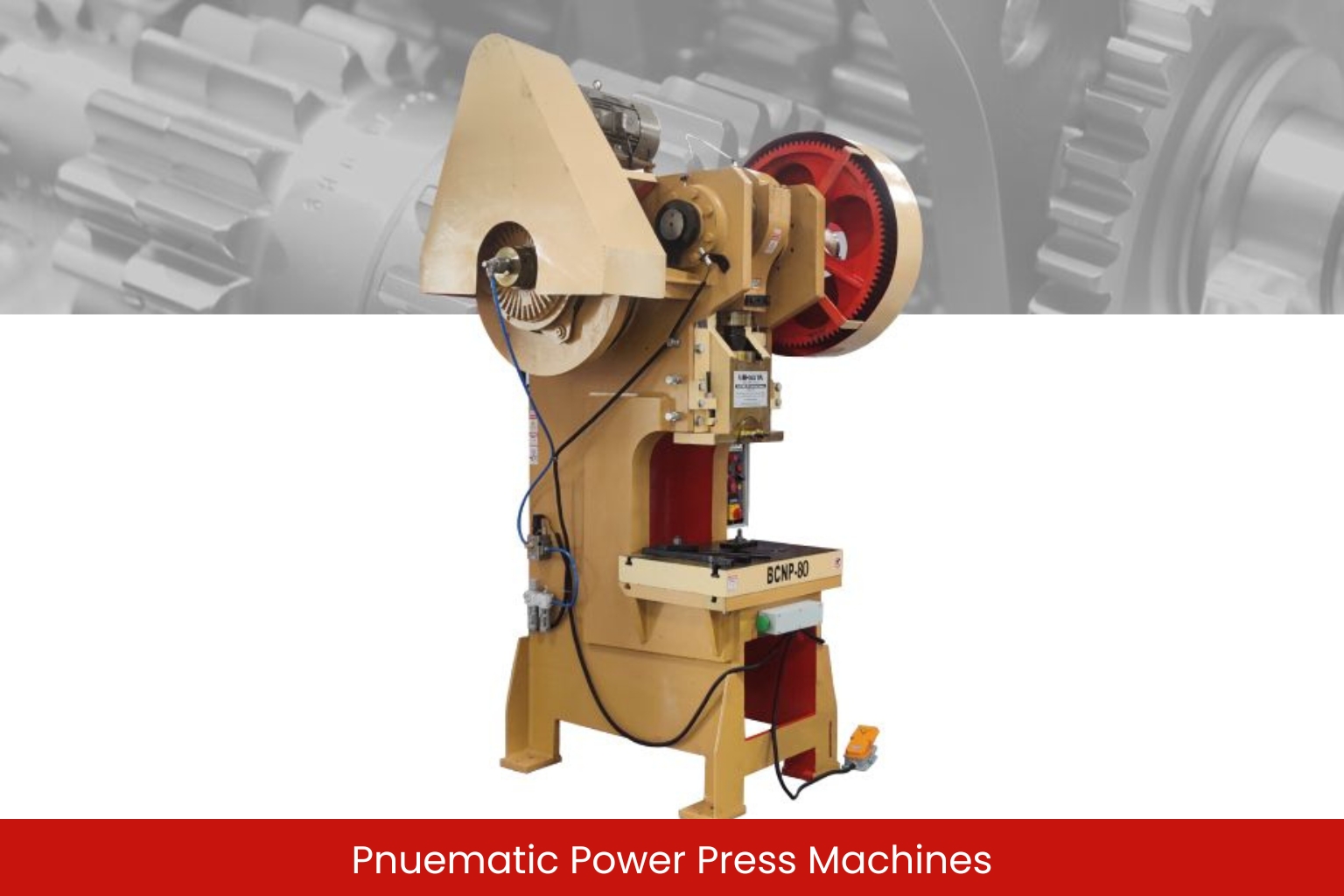

- Hydraulic & Power Presses: Engineered for deep drawing and stamping, these machines are the workhorses of the appliance and automotive component industries.

Read Our Article

The Milling Machine Tools Industry in DubaiAdvanced Technology: CNC and Fiber Lasers

The 2026 market is defined by automation. Bhavya is meeting this demand head-on with its advanced technology division.

- CNC Lathe Machines: These systems provide the ultimate in precision and repeatability, allowing manufacturers in Europe and North America to compete on quality while optimizing labor costs.

- Fiber Laser Cutting Machines: In 2026, fiber laser technology has matured into the most cost-effective way to cut sheet metal. These machines offer incredible speed, zero contact (reducing tool wear) and the ability to cut complex geometries with ease.

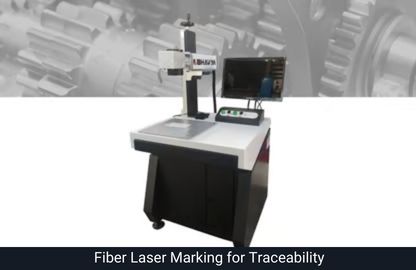

- Fiber Laser Marking Machines: Essential for traceability and branding, these machines provide permanent, high-contrast marks on various metallic surfaces.

Precision Grinding & Finishing

For industries where a fraction of a micron matters, Bhavya’s grinding solutions provide the answer.

- Surface & Centerless Grinding: Designed for achieving mirror-like finishes and exact tolerances on cylindrical and flat surfaces.

- Saw Blade Sharpeners: A specialized addition to the portfolio that helps manufacturers maintain its own tooling, significantly reducing operational overheads.

Serving the Global Market: From the Middle East to the Americas

Bhavya Machine Tools is not just an Indian brand; it is a global partner. The 2026 exhibition is specifically tailored to address the unique requirements of various international regions:

- Middle East (UAE, Saudi Arabia, Qatar): With a dedicated branch in Dubai, we understands the region’s focus on oil and gas, construction and rapid industrial diversification. Our heavy-duty lathes and hydraulic presses are ideal for the demanding environments of the Gulf.

- Europe and North America (USA, Canada): In these markets, the emphasis is on Industry 4.0 and CNC precision. Our CNC range and Fiber Laser systems offer the high-tech features required to meet stringent Western quality standards at a competitive price point.

- Africa and Asia: These emerging markets require “right-fit” technology – machines that are robust, easy to maintain and highly productive. Bhavya’s manual machines and specialized tools like Bandsaws and Hacksaws provide the perfect entry point for industrial growth.

Our Other Machine

Drill Bit Re-SharpenerConclusion: The 2026 Industrial Shift with Automation and Sustainability

At AMTEX 2026, the conversation will revolve around “Green Manufacturing.” Bhavya Machine Tools’ is contributing to this by showcasing machines with:

- Energy-Efficient Motors: Reducing the carbon footprint of the factory floor.

- Reduced Material Waste: High-precision cutting and shearing technologies ensure that every millimeter of raw material is utilized.

Many of the machines featured at Stall A-29 allowing managers to monitor performance and predictive maintenance through digital dashboards.