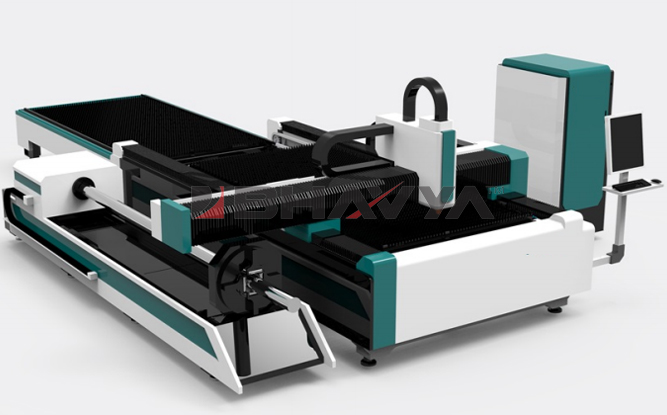

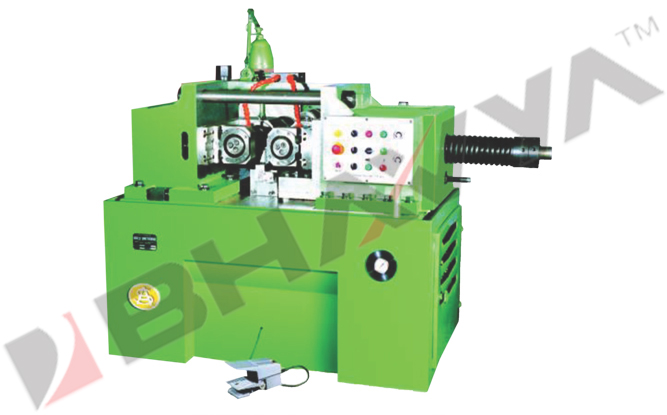

Bolt threading machines provide high-quality machining services, maintaining consistency when threading various pipes and bolts. They are ideal for many industries, particularly those in harsh environments, which require consistent, reliable output and durability. Threading is a crucial process that directly influences the performance and life of the final product. This is why choosing the right machine is so important.

Why Buy Bolt Threading Machine?

The most common thread used in these machines is aluminium and stainless steel, though other materials such as brass, bronze, copper, nickel, and tin can be used to create precision tubes and bolts. Bolts can be produced using either soft steel or soft aluminium, with stainless steel being the best for high-quality bolt heads. The machines allow for a variety of thread sizes, ranging from very small through to large, providing the user with the ability to produce the perfect size of bolt or pipe for their application. Threading machines usually have a specialized feeding system, which enables them to feed continuously and evenly, ensuring a perfect fit every time. This results in less wastage and more accurate work.

Working Principle of Bolt Threading Machine

To ensure optimal performance, the threader must also have a high level of strength, so that it can support both the torque and the weight of the product and the final diameter of the spindle bore. Bolts used in this application should be designed to withstand extreme stresses and they should be manufactured using high-quality alloy steel. The strength of the bolt threading machine, its feed rate, the spindle bore diameter, the bolt thread speed, and the diameter of the product are all taken into consideration before the machine is designed and built to manufacture these essential products.

How to Choose a Bolt Threading Machine?

When choosing a bolt threading machine it is important to identify its specific application to determine whether it is intended for use in only one particular area or if it can be used in a wide variety of conditions. This will determine the size of the machine and the different types of bolts that can be used. There are many machine types available, including those that can produce flexible brass or PVC straps, as well as much bigger machine designs capable of producing extremely heavy-duty pipes, corrugated tubes, and even sheet metal. When identifying your needs, it is important to take note of both the strength and the size of the project and the types of bolts that will be required.

Factors that Determine Capacity of Bolt Threading Machine

The overall capacity of the bolt threading machine is determined by several factors, including the diameter of the pipe or cylinder, the bolt diameter, and the tensile strength of the material used to manufacture the product. Many machine manufacturers will provide data sheets that can help you identify your unique requirements and determine the potential capacity that your machinery can deliver. In addition to the potential capacity of the machine, it is also important to take note of the environment it will be working in, as both the pipe threader and the work area will need to withstand extreme temperatures. Depending on your industry and the type of work, it may be necessary to upgrade your pipe threader to meet your company’s needs.

The Bottom Line

Before purchasing any type of bolt threading machine, it is important to ensure that you receive complete product details. These details should provide information on the machine and the specific application it will run. It should detail both the mechanical and electrical specifications of the machine as well as detailed information on the possible configuration that could be required. If possible, it is always a good idea to compare the specifications from different suppliers, ensuring that you pay close attention to the machine that best meets your specific needs.

WhatsApp!

WhatsApp!