Punjab has emerged as India’s one of the most industrially advanced states. The demand for specialized industrial machine tools has risen significantly over the years in Punjab state, thanks to rapid industrialization and the rise of small and medium-sized businesses. These businesses require many machine tools to meet diverse needs such as cutting, sharpening, polishing, grinding, and finishing hard materials for various industries. Machine tools play a crucial role in the manufacturing industry as they help you save time and ensure that you deliver the highest-quality solutions. Let us take a look at the varied machine tools used in the Industrial sectors of Punjab so that you get a glimpse at the most in-demand machine tools used in the industry.

Top 15 Machine Tools that Meet the Rising demand of the Industrial Sectors of Punjab!

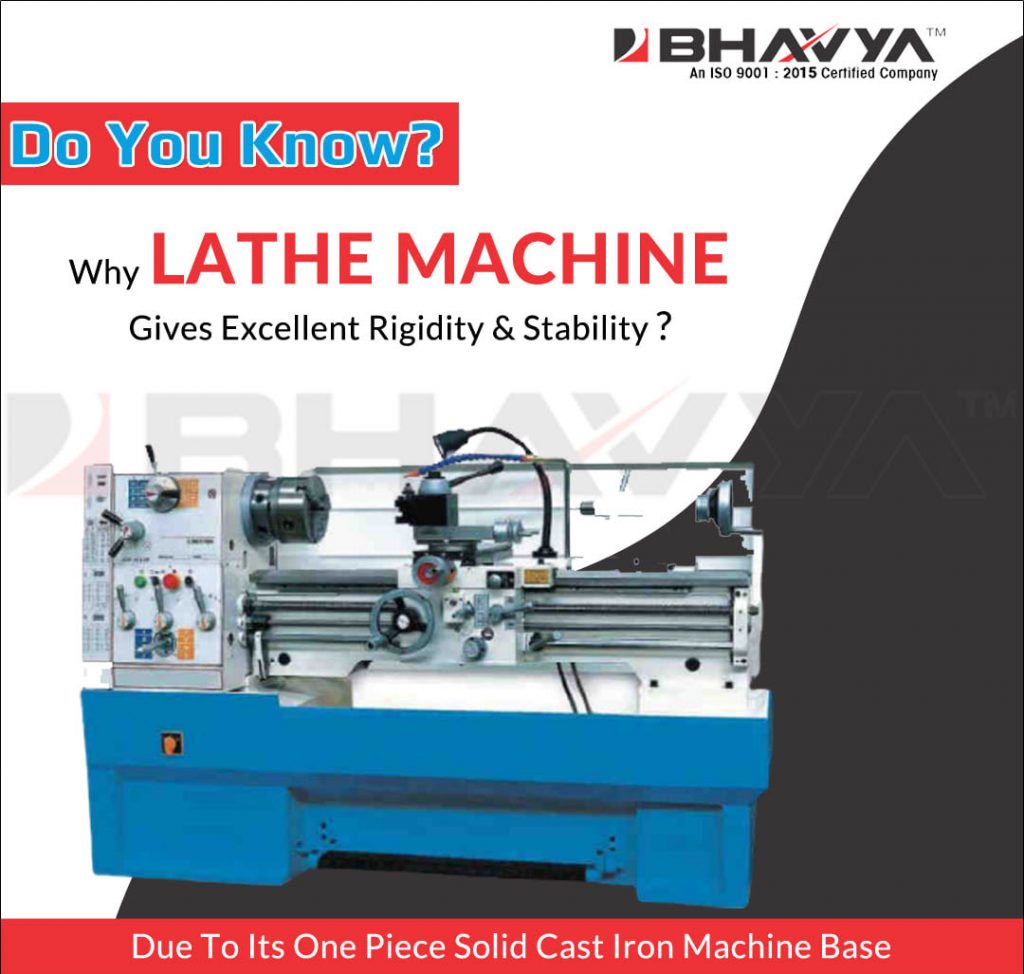

● All Geared Lathe Machines in Punjab for Precision

This sturdy equipment helps you to shape even the hardest metals. All Geared Lathe Machines in Punjab can handle high-duty applications for metal forming in bulk in various industries. You can precisely cut the material and give it the desired shape for the best results. With a high-speed spindle, this robust equipment is most suitable for industries that involve bulk production such as mining, paper industry, automotive industry, and many others.

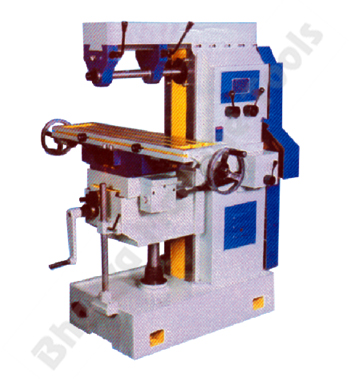

● Milling Machine in Punjab for High-Speed Operations

A milling machine in Punjab helps you to cut and shape solid materials at the highest speed. This machine works differently than a lathe machine as the former has multiple-point cutting tools, whereas the latter only uses a single-point cutting tool. A milling machine in Punjab is most suitable for operations where speed is the priority.

● Radial Drilling Machine in Punjab for Better Drilling

A radial drilling machine in Punjab has found its application in crucial metalwork for drilling purposes. In comparison to a traditional drilling machine, a radial drilling machine in Punjab provides greater accuracy and can help to drill holes of different sizes.

● Cutting Edge Bandsaw Machine in Punjab

Bandsaw machines in Punjab can accommodate diverse materials and shape them in the desired manner. With a bandsaw machine in Punjab, you can cut the material into straight, curved, or any irregular shape. With smooth functioning, you can use the versatile tool across industries such as metalworking, lumbering, and woodworking.

● Hacksaw Machine in Punjab for Sharpness

With sharp teeth and cutting-edge technology, a hacksaw machine in Punjab is most suitable for cutting hard plastic, wood, and metals. An automatic hacksaw machine in Punjab will help you move up your production process and carry out operations in a hassle-free manner.

● Slotting Machine in Punjab for Production in Slots

Manufacturers in Punjab need efficient machines for handling large and awkward pieces. This is where slotting machines can help. A slotting machine in Punjab can help in cutting grooves, keyways, and slots of various shapes for a well-defined surface. Since they are economical and can handle bulk production, they have found usage in paper mills, steel mills, tool rooms, textile factories, and others.

● Hydraulic Press in Punjab for Versatility.

A hydraulic press in Punjab comes equipped with hydraulic cylinders for assembling parts, compressing materials, and manufacturing various automotive parts. The versatility of this machine plays a major role in the manufacturing industry of Punjab state. Right from automobile, medical to metal forming, you can use a hydraulic press in Punjab to make even the most complex parts.

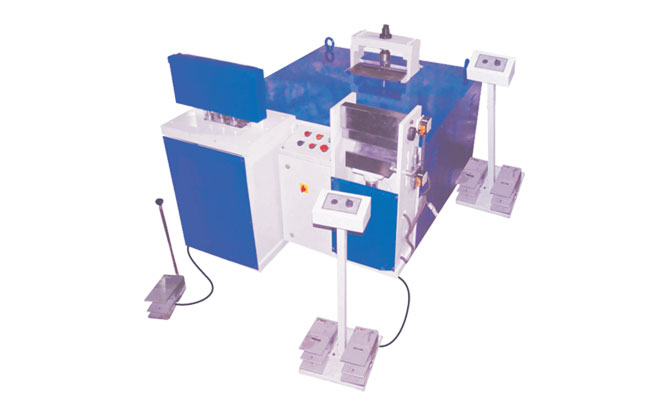

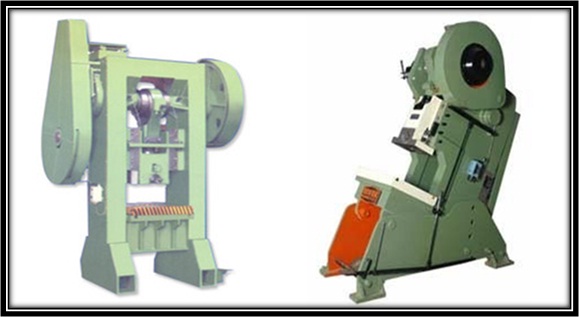

● Power Press in Punjab for Perfect Molding & Formation

Complicated metal pieces require adequate pressure to ensure that they turn into well-defined pieces. With a power press in Punjab, you can simplify metal bending tasks for greater work proficiency. For heavy industrial applications such as factories and engineering plants, this equipment helps in proper assembling, drawing, and straightening. The compact size of the c type power press in Punjab makes it an ideal choice for long-term use.

● Fibre Laser Marking & Cutting Machine in Punjab

Fibre laser marking machine in Punjab is one of the most well-acknowledged systems in Punjab because of its high-speed marking application in the pharmaceutical, beverages, and other industries. A fibre laser marking machine in Punjab is suitable for excellent product traceability and identification. You can also use the machine for engraving and marking on diverse materials with ease and precision.

A fibre laser cutting machine in Punjab, on the other hand, caters to the pharmaceutical, electronics, and textile industry of Punjab for cutting smaller and complicated parts. Its extreme accuracy, clean cuts, and ability to cut through tough as well as delicate materials make it suitable for custom operations.

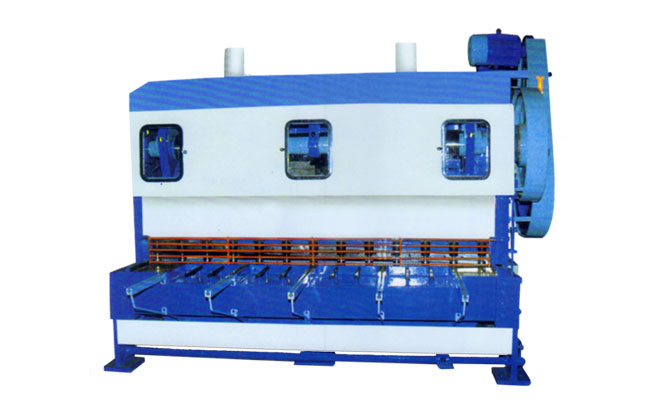

● Shearing Machine in Punjab for High-Output Operations

With a shearing machine in Punjab, you can cut soft metals such as aluminum, brass, bronze, and others into straight-line cuts for a faster and efficient production process. A shearing machine in Punjab uses a greater force to cut through the material without forming chips or burning the metal. The machine can help you cut thousands of pieces per hour to ensure that you can meet all demands on-time.

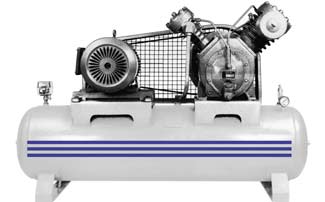

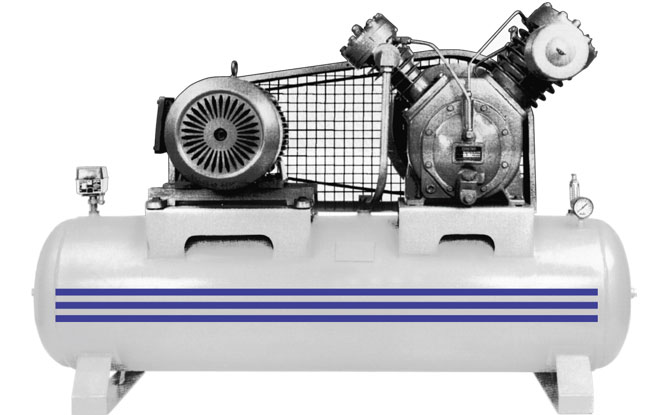

● Air Compressors in Punjab for Varied Industrial Uses

Besides manufacturing, Punjab is one of the most agriculturally rich states in India. An air compressor in Punjab caters to various industrial needs such the agriculture, manufacturing, construction, food, and many others. Right from heating, ventilation, and cooling, air compressors in Punjab can help in a variety of operations to suit your business needs. If you are looking for a reliable air compressor, it is best to choose the one that caters to your specific industry.

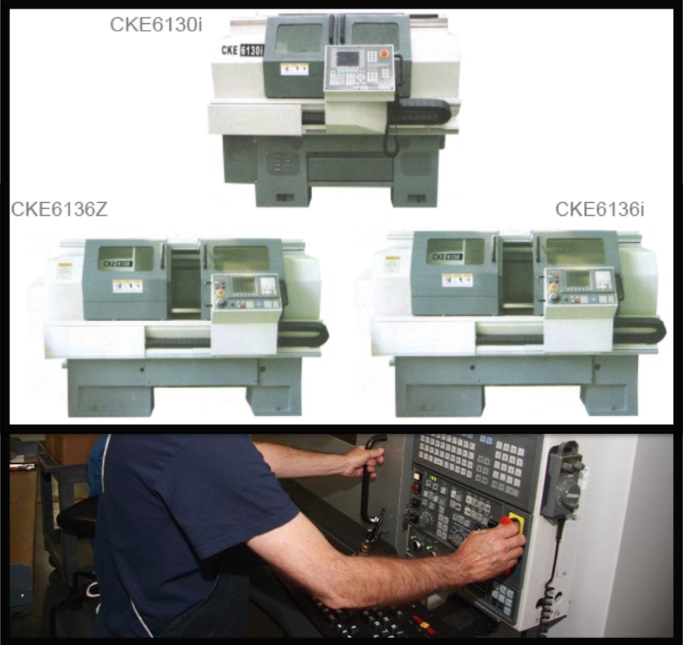

● CNC Machining Centre in Punjab for Advanced Operations

A CNC machining centre in Punjab can perform drilling, shaping, and lathe operations. This advanced machinery can help manufacturers in Punjab perform multiple actions with a single machine to produce a finished product. CNC machining centre in Punjab is available in many types to suit your business needs. The machining centre allows manufacturers in Punjab to automate various processes for enhancing productivity and eliminating waste. Now, process your orders faster and make deliveries on-time.

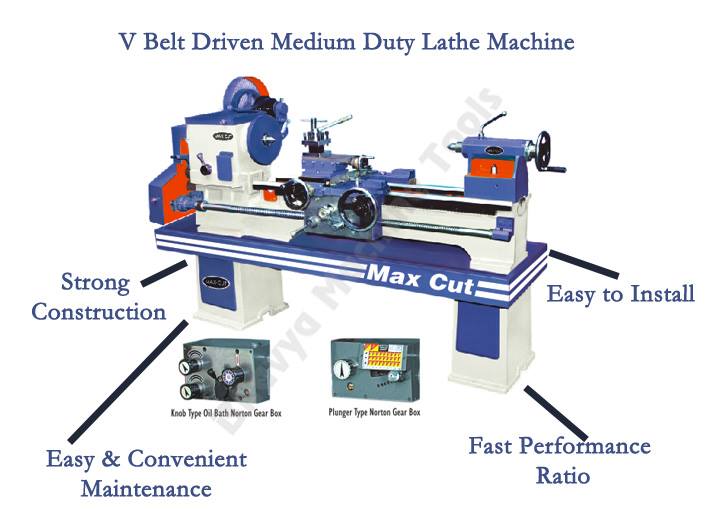

● Latest Technology V Belt Drive Lathe Machine in Punjab

A lathe machine helps manufacturers give shape to hard materials. Similarly, a V-belt drive lathe machine in Punjab is designed to shape hard materials albeit in a faster and more efficient manner. This latest technology equipment has more power transmission capacity than a flat belt and the setup encourages heavy-duty operations even at high-speed. A v-belt drive heavy duty lathe machine in Punjab helps to meet the specific requirements of the industry and creates objects that have symmetry.

● Dynamic Drilling & Tapping Machine in Punjab

Drilling and tapping machine in Punjab helps manufacturers to fasten two pieces of metal together and also helps in drilling a hole. This dynamic equipment combines drilling and tapping for mass production and has found widespread usage in the automobile and aerospace industries. Since this machine is available in various sizes, you can choose the one that best suits your needs.

● Plate Rolling Machine in Punjab

The plate rolling machine in Punjab is an essential production element that helps to bend large metal sheets into a cylindrical arc or in the desired shape. With fast processing speed, this machine can help you cut and roll the metal plate without any warping. Ensure that all your metal sheets are in the shape you desire with a plate rolling machine in Punjab.

![Lathe Machine - Types & Applications of Lathe Machines [INFOGRAPH]](https://machinetools.bhavyamachinetools.com/wp-content/uploads/2013/07/bhavya-july1-170x1024.jpg)

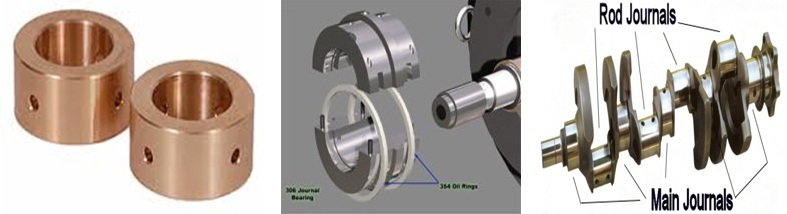

The main types of bearings are ball, roller and the journal bearings. All these require the

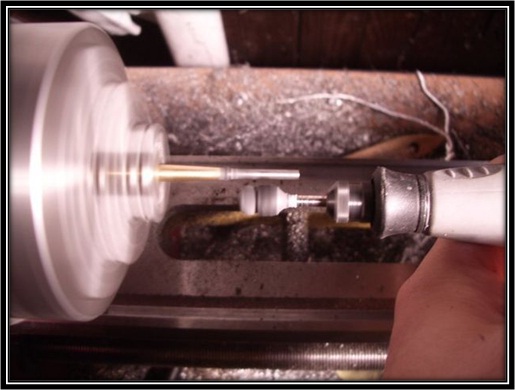

The main types of bearings are ball, roller and the journal bearings. All these require the  These have an outer and inner race, the ball and cage to mount and hold the balls. Specially designed lathes are used to turn cylindrical work pieces in large quantities to form the inner and outer race. The turning operation ensures that the inner and outer rings of bearing have very accurate and precise diameters that meet the tolerance limits.

These have an outer and inner race, the ball and cage to mount and hold the balls. Specially designed lathes are used to turn cylindrical work pieces in large quantities to form the inner and outer race. The turning operation ensures that the inner and outer rings of bearing have very accurate and precise diameters that meet the tolerance limits. These have rollers instead of balls. They are used in heavy loading applications such as gears, transmission shafts and areas with high axial thrust. Again turning and facing operations are performed using this

These have rollers instead of balls. They are used in heavy loading applications such as gears, transmission shafts and areas with high axial thrust. Again turning and facing operations are performed using this  They are applied in all internal combustion engines and forms the rotating parts of crank shaft. They are also used in large turbines, motors and heavy machinery where roller and ball types cannot be used. Essentially, this device is made of two rotating parts that slide along each other.

They are applied in all internal combustion engines and forms the rotating parts of crank shaft. They are also used in large turbines, motors and heavy machinery where roller and ball types cannot be used. Essentially, this device is made of two rotating parts that slide along each other. For journal to function effectively, they must be smoothened. This is achieved using lapping operation. The cylindrical work piece is rotated against smooth abrasive material to remove a very small layer of materials and achieve high quality and extra smooth surface.

For journal to function effectively, they must be smoothened. This is achieved using lapping operation. The cylindrical work piece is rotated against smooth abrasive material to remove a very small layer of materials and achieve high quality and extra smooth surface. Tracing the adaptations

Tracing the adaptations  Historical background

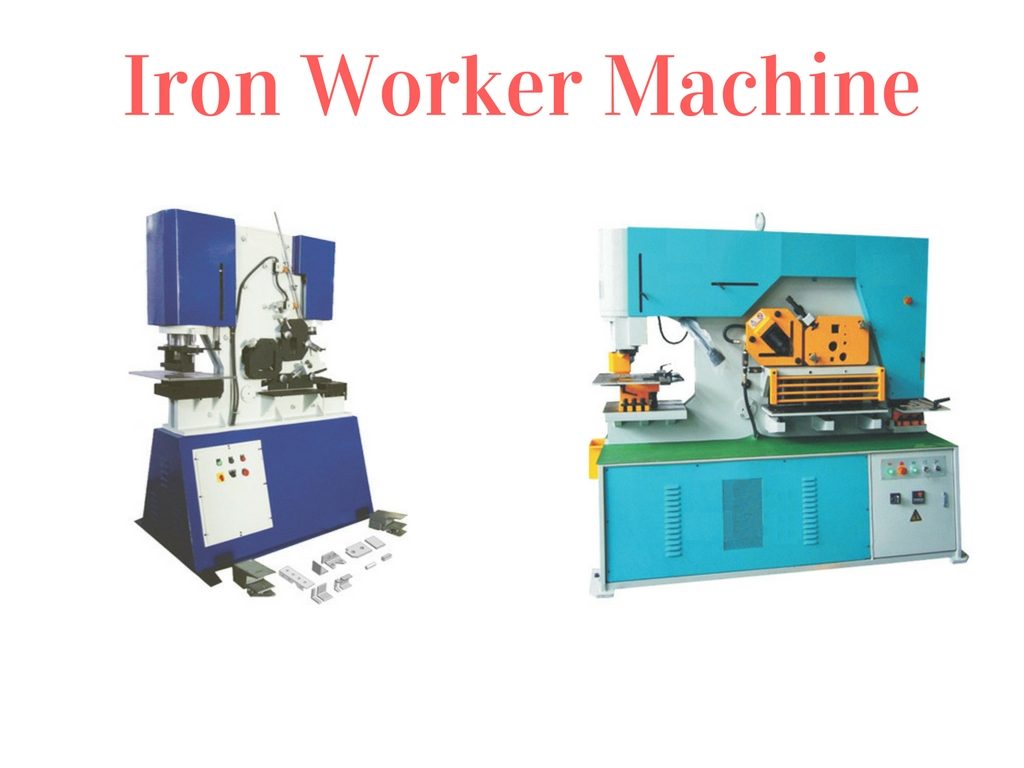

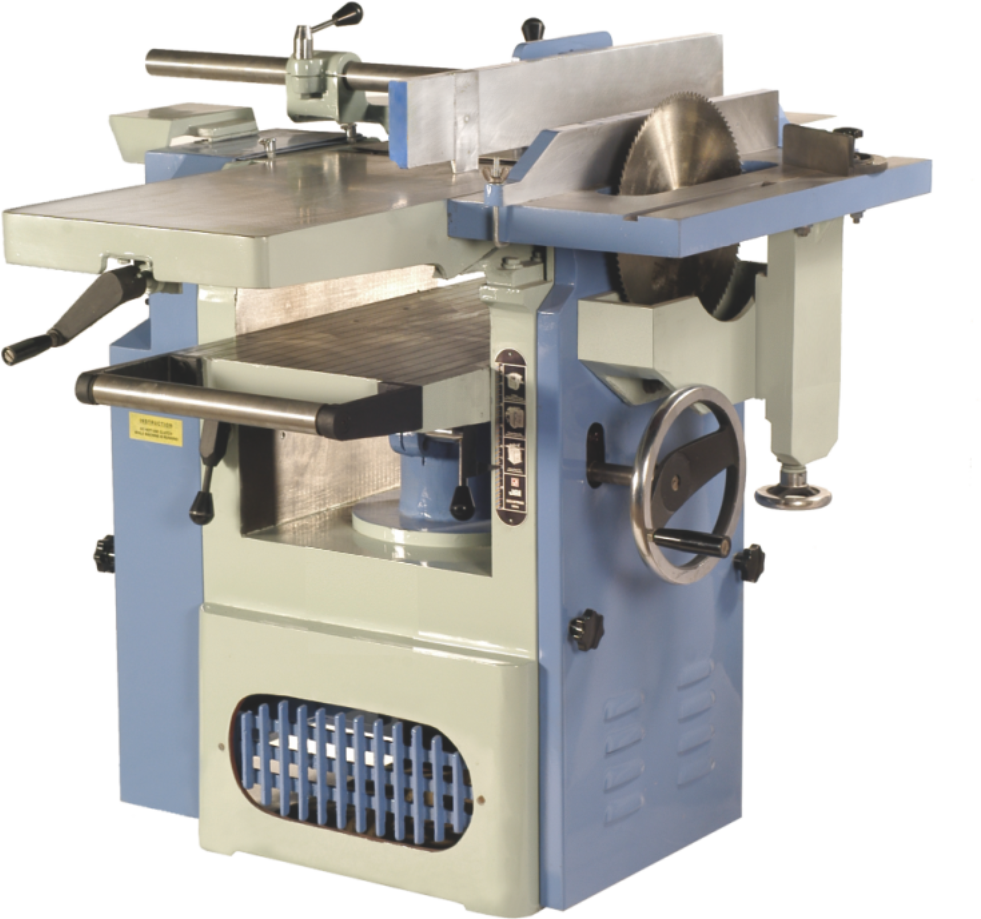

Historical background  Milling Machine in Batch Manufacturing Of Components

Milling Machine in Batch Manufacturing Of Components  The Planning Machine: Operation and Utilization

The Planning Machine: Operation and Utilization  Manufacturing of parts such as fuel injectors requires very high precision. Camshafts’ grinding is also a core application of

Manufacturing of parts such as fuel injectors requires very high precision. Camshafts’ grinding is also a core application of  Turning

Turning  Automotive parts made through turning.

Automotive parts made through turning. Terms and Conditions in Online Shops

Terms and Conditions in Online Shops  Importance of workshops in Manufacturing

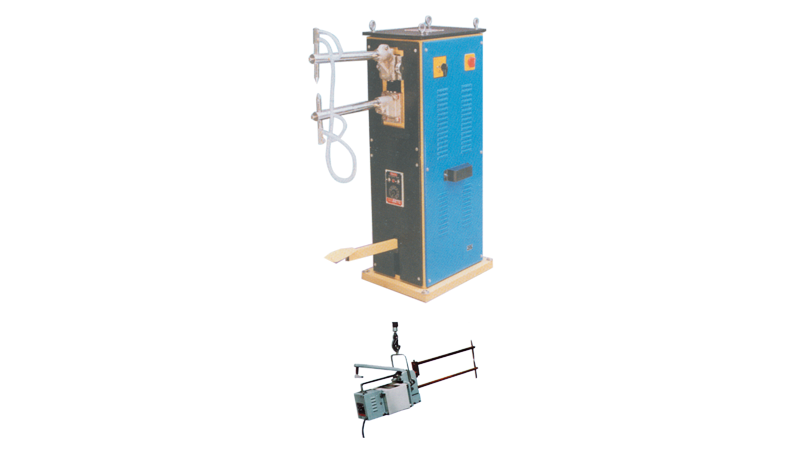

Importance of workshops in Manufacturing  Liquid filling Machinery components servicing

Liquid filling Machinery components servicing Use of power press in making metallic bottle caps

Use of power press in making metallic bottle caps  Critical parameters that must be achieved

Critical parameters that must be achieved  The straight side type is widely used for inline mass production. It has two vertical arms on the sides. It has a strong housing on the top part that house the crankshaft. They have crankshaft and pulleys that change the type of motion.

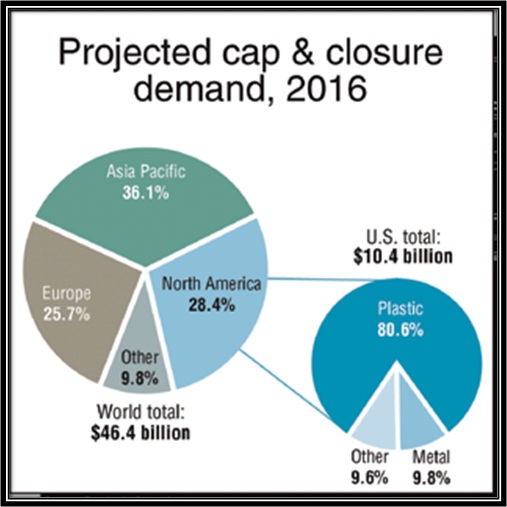

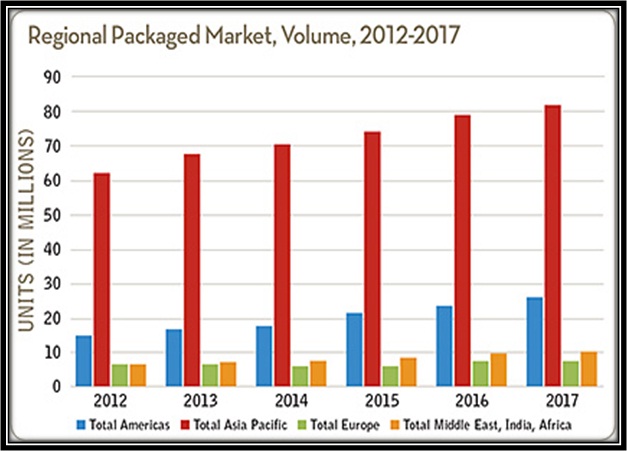

The straight side type is widely used for inline mass production. It has two vertical arms on the sides. It has a strong housing on the top part that house the crankshaft. They have crankshaft and pulleys that change the type of motion. With the increasing number of foods, cosmetics and pharmaceutical industry requiring metal and plastic caps, the market is expected to rise gradually in the next 5 years. The use of metallic caps is however facing stiff competition from the cheaper plastic that contributes to over 80% of all the closures. In 2013, the closures market accounted for US$ 40 billion and this is expected to rise to US$ 43Billion (5.3%). US market closures consist of 80.6 % plastics and 9.8% metals. However, with the negative environmental impacts associated with plastics, the metallic closures are expected to take a larger portion.

With the increasing number of foods, cosmetics and pharmaceutical industry requiring metal and plastic caps, the market is expected to rise gradually in the next 5 years. The use of metallic caps is however facing stiff competition from the cheaper plastic that contributes to over 80% of all the closures. In 2013, the closures market accounted for US$ 40 billion and this is expected to rise to US$ 43Billion (5.3%). US market closures consist of 80.6 % plastics and 9.8% metals. However, with the negative environmental impacts associated with plastics, the metallic closures are expected to take a larger portion.

Contractors specializing in fabrication of many custom items have to make numerous rings that differ in design. This is achieved by using CNC machine. The jewels are automatically made by adjusting the tools and feed. In addition, these devices have the capacity of not only performing the turning, facing and other conventional lathe work but can also mill and perform cylindrical grinding.

Contractors specializing in fabrication of many custom items have to make numerous rings that differ in design. This is achieved by using CNC machine. The jewels are automatically made by adjusting the tools and feed. In addition, these devices have the capacity of not only performing the turning, facing and other conventional lathe work but can also mill and perform cylindrical grinding. They are characterized by minute tool post and chuck which are designed to handle tiny work pieces. Their bed is machined to perfect straightness. They are also fitted with a plate chuck which assists in holding complex shaped work pieces. They have a smaller bed, tailstock, head stock and carriage. These machines also have low power consumption and are very efficient. They are compact, durable and have excellent functionality.

They are characterized by minute tool post and chuck which are designed to handle tiny work pieces. Their bed is machined to perfect straightness. They are also fitted with a plate chuck which assists in holding complex shaped work pieces. They have a smaller bed, tailstock, head stock and carriage. These machines also have low power consumption and are very efficient. They are compact, durable and have excellent functionality. The shape of the container allows easy stacking on top of each other. Since they are manufactured from high strength materials and locked, they are intrusion free. They also have identification number allowing for easy tracking via GPS and RFID.

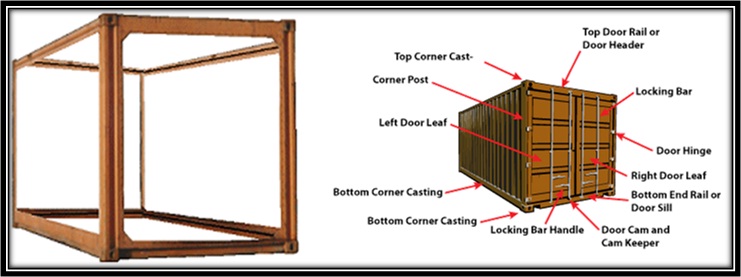

The shape of the container allows easy stacking on top of each other. Since they are manufactured from high strength materials and locked, they are intrusion free. They also have identification number allowing for easy tracking via GPS and RFID. Aluminum types are made of steel frames while the sides, front, back, roof and bottom are made with high strength durable aluminum.

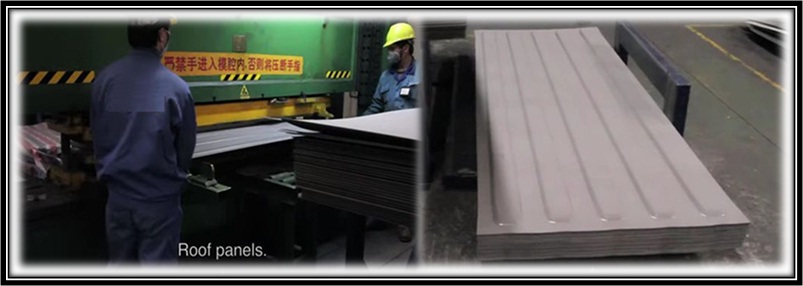

Aluminum types are made of steel frames while the sides, front, back, roof and bottom are made with high strength durable aluminum. The roof panels are made pressing using a specially designed press brake machine. This device punch presses the plate against the die to form the intended shape.

The roof panels are made pressing using a specially designed press brake machine. This device punch presses the plate against the die to form the intended shape. The floor frame is then made by cutting the plate using a shearing machine and these are folded using a press brake machine. This machine folds the material forming a U shaped bracket. A series of these brackets are welded to form a very strong base.

The floor frame is then made by cutting the plate using a shearing machine and these are folded using a press brake machine. This machine folds the material forming a U shaped bracket. A series of these brackets are welded to form a very strong base.

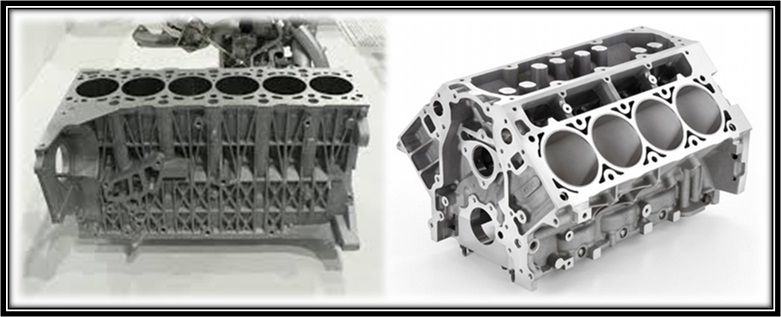

Tractor engine (Inline and V type): numerous holes and attachments done with radial drill

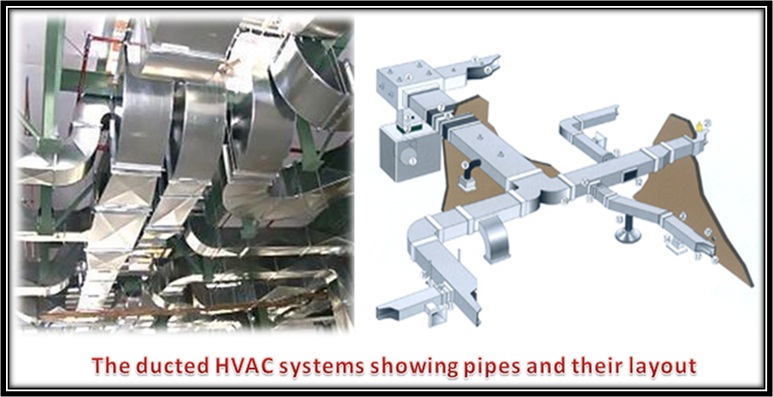

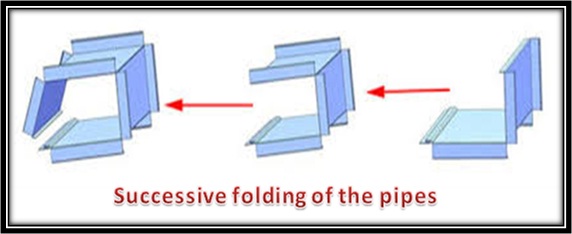

Tractor engine (Inline and V type): numerous holes and attachments done with radial drill Role of bending machines in fabrication of these systems

Role of bending machines in fabrication of these systems  Special features

Special features  In 2012, the global AC market was valued at US$86.8 billion and US$91.6 billion in 2013. The Asia pacific region has the highest demand due to rising industrial, commercial and residential sectors. The main units demanded are roof tops, indoor packaged, chiller plants and central ducted types.

In 2012, the global AC market was valued at US$86.8 billion and US$91.6 billion in 2013. The Asia pacific region has the highest demand due to rising industrial, commercial and residential sectors. The main units demanded are roof tops, indoor packaged, chiller plants and central ducted types.