Introduction

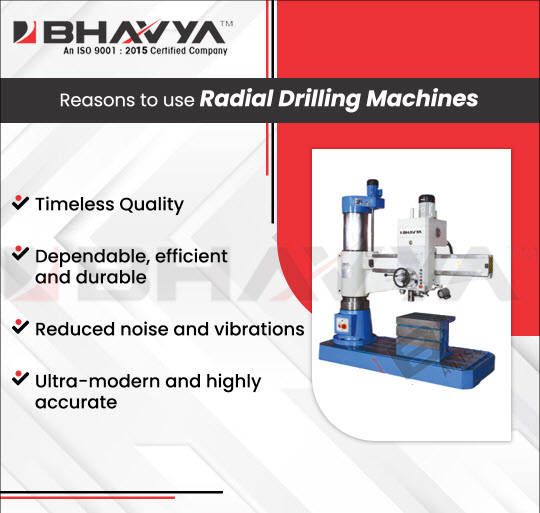

Drilling is a fundamental operation in many industries, requiring precision and efficiency to achieve the desired results. Bhavya Machine Tools, a leading manufacturer of radial drilling machines in India, offers a range of V-belt driven radial drilling machines designed to meet the diverse needs of industries in Lucknow. These machines, known for their compatibility, durability, and high performance, are essential tools for any workshop aiming to achieve precision in drilling operations. This article explores the features, advantages, and applications of Bhavya’s radial drilling machines, emphasizing their significance in enhancing machining accuracy in Lucknow.

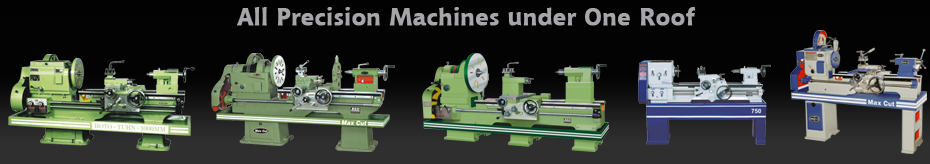

Diverse Models for Varied Drilling Needs

Bhavya Machine Tools offers a wide range of V-belt driven radial drilling machines, including models with 25mm, 38mm, and 40mm radial boring capabilities. These machines are designed to perform precision drilling in various types of metal pieces, making them suitable for a broad spectrum of industrial applications. The different models cater to specific needs, ensuring that every drilling requirement can be met with the highest level of accuracy and efficiency.

Key Features of Bhavya Radial Drilling Machines

- High-Quality Construction:

- Bhavya’s radial drilling machines are constructed using the finest quality materials, ensuring durability and reliability. This robust construction allows the machines to withstand long-term production demands, making them a valuable investment for workshops in Lucknow.

- Precision and Accuracy:

- These machines are designed for precision drilling, with varied spindle travel to achieve exact positioning. The accuracy of Bhavya’s radial drilling machines makes them ideal for creating precise holes in different materials, a critical requirement in many industries.

- Low Noise and Vibration:

- One of the standout features of Bhavya’s radial drilling machines is their low noise and reduced vibrations during operation. This ensures a quieter working environment and minimizes wear and tear on the machine, enhancing its longevity and performance.

- Ease of Operation and Maintenance:

- Bhavya’s machines are designed for simplicity and ease of use. Their user-friendly design ensures that even operators with minimal training can use the machines effectively. Additionally, these machines require low maintenance, reducing downtime and operational costs.

- Compatibility and Versatility:

- The radial drilling machines are compatible with essential components such as the arm, column, and drill head, allowing for adjustments in height and rotation. This versatility ensures that the machines can handle a variety of drilling tasks, from simple holes to more complex operations.

- Customization Options:

- Bhavya Machine Tools also offers customized options to meet specific industrial standards and requirements. This flexibility allows workshops to tailor the machines to their unique needs, enhancing their overall efficiency and productivity.

Specific Models and Their Specifications

- 25mm, 38mm, and 40mm Radial Boring Machines:

- These models are equipped with V-belt driven mechanisms, providing varied spindle travel for precision drilling. They are ideal for different types of metal pieces, ensuring precise and efficient drilling operations.

- R-40G All Geared Radial Drilling Machine:

- The R-40G model is an all-geared radial drill machine, known for its sturdy construction and reliable performance. It is designed for making holes in various materials, offering a robust, economical, and durable solution for drilling operations.

Applications of Radial Drilling Machines in Lucknow

The radial drilling machines from Bhavya Machine Tools find applications in a wide range of industries in Lucknow. Their precision, durability, and versatility make them indispensable tools in various sectors:

- Manufacturing Industry:

- In the manufacturing sector, these machines are used for drilling precise holes in metal components, essential for producing high-quality products. Their ability to handle different materials makes them suitable for various manufacturing processes.

- Automotive Industry:

- The automotive industry relies on precise drilling operations to create components for vehicles. Bhavya’s radial drilling machines provide the accuracy and reliability needed to produce durable and high-performance automotive parts.

- Construction Industry:

- In construction, these machines are used for drilling holes in metal structures, ensuring stability and strength. Their robust construction and precision capabilities make them ideal for heavy-duty construction tasks.

- Aerospace Industry:

- The aerospace sector demands high precision in the manufacturing of aircraft components. Bhavya’s radial drilling machines meet these stringent requirements, ensuring that each part is crafted with the utmost accuracy.

- General Workshops:

- For general workshops, the versatility and ease of operation of Bhavya’s machines make them a go-to choice for a variety of drilling tasks. Their low maintenance and high performance ensure that workshops can operate efficiently with minimal downtime.

Conclusion

Bhavya Machine Tools’ radial drilling machines offer a comprehensive solution for precision drilling needs in Lucknow. With diverse models catering to varied requirements, high-quality construction, and advanced features, these machines enhance the efficiency and accuracy of drilling operations across different industries. Whether for manufacturing, automotive, construction, aerospace, or general workshops, Bhavya’s radial drilling machines provide the reliability and performance needed to meet the demands of modern industrial applications. Investing in these machines ensures that workshops in Lucknow can achieve high-quality production with minimal operational costs, making them a valuable addition to any industrial setup.

WhatsApp!

WhatsApp!