A press brake is primarily used for accurately bending various types of metal sheets and plates. Some frequently asked questions are as follows:

A press brake is primarily used for accurately bending various types of metal sheets and plates. Some frequently asked questions are as follows:

Q. What is camber?

A. Camber is actually a small piece of cap which is placed on the ram or bed to permit deflection. This is due to the fact that, any material which is bent on a it will encounter resistance. As a result this resistance will deflect the bed as well as the ram.

Q. Is it necessary to fasten the machine to the floor?

A. Definitely, the press brake must be first leveled and then properly fastened to the floor. Otherwise 25 percent of the energy of your press brake will be wasted, due to loss of torque.

Q. How much tonnage is required for a specific task?

A. Please refer the chart on the press brake which displays the amount of tonnage needed for a specific kind of metal. For example, you can press a 0.25 inch steel plate at 15.4 tons per foot. Further, in case you are using a 0.125 inch sheet, it can be pressed at 7.7 tons per foot.

Q. Explain tensile strength and yield strength for a press brake?

A. The term tensile strength is used when you are referring to pressing a metal piece. This includes applying lots of force at a particular place on the metal piece to accomplish the task. Whereas yield strength refers to applying relatively less force in order to roll a metal piece. Hence in order to press stainless steel or any other metal, you will require a larger press brake as the tensile strength is more than 80000. On the other hand, for rolling stainless steel, you may use a smaller capacity press brake. For example, a 304 stainless steel work piece actually has a tensile strength of 95000; while the yield strength is just 35000.

Q. Why is it essential to designate the various materials?

A. Material designation is important as well as mandatory, since it provides us the detailed information of a particular metal; including the tensile strength and yield strength. Moreover, it is also necessary to ensure that you have the complete designation of a metal. For instance, A516 is incomplete and not sufficient. You must also include the grade. Hence A516-55 means that the tensile strength is 55-75000 and the minimum yield strength is 30,000. And A516-70 refers to tensile strength of 70-90,000; and minimum yield strength of 38000.

Q. What is the maximum capacity of a press brake?

A. The maximum capacity is basically, the rated tonnage of the tools. Hence you should find out the relevant tonnage per foot, and then just multiply the tonnage by the number of feet you require. However, while using short pieces of metal, it is always advisable to slightly move the work piece in order to prevent the bed from getting damaged.

Hence these FAQs on press brake will help potential and existing users to solve their queries.

machine, and H type power press machine. A hydraulic press uses a hydraulic cylinder for generating compressive force, which is the hydraulic equivalent of a mechanical lever. It is mainly used for hydro forming. The industrial hydraulicis a sturdy, energy efficient and durable machine that is used for hydraulic applications in numerous industries.

machine, and H type power press machine. A hydraulic press uses a hydraulic cylinder for generating compressive force, which is the hydraulic equivalent of a mechanical lever. It is mainly used for hydro forming. The industrial hydraulicis a sturdy, energy efficient and durable machine that is used for hydraulic applications in numerous industries.

The bandsaw machine is one of the most essential tools widely used for woodworking, metalworking and cutting a variety of materials into straight, curved and irregular shapes. Nowadays, a wide range of bandsaw equipments are available in the market. They are built as per the industry standards, and each model has various features and different specifications. Hence, choosing the required bandsaw device may be difficult and confusing. You should therefore take into account the following features while selecting it.

The bandsaw machine is one of the most essential tools widely used for woodworking, metalworking and cutting a variety of materials into straight, curved and irregular shapes. Nowadays, a wide range of bandsaw equipments are available in the market. They are built as per the industry standards, and each model has various features and different specifications. Hence, choosing the required bandsaw device may be difficult and confusing. You should therefore take into account the following features while selecting it. Some have smaller depth of cut. Hence an optional riser is required to extend the depth. And the throat refers to the distance from the blade to the vertical frame of the bandsaw. This distance is related to the width of the cut that can be executed by the machine. For example a 12 inch band saw is basically the throat size of that model. So select the appropriate model, based on the material to be cut.

Some have smaller depth of cut. Hence an optional riser is required to extend the depth. And the throat refers to the distance from the blade to the vertical frame of the bandsaw. This distance is related to the width of the cut that can be executed by the machine. For example a 12 inch band saw is basically the throat size of that model. So select the appropriate model, based on the material to be cut.

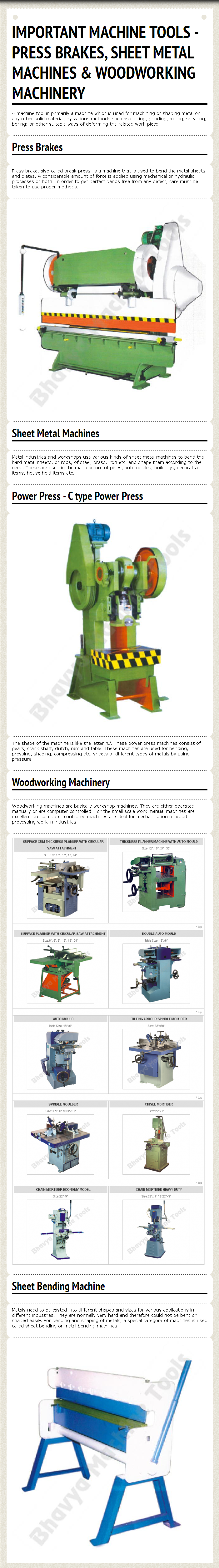

Today, several types of machines, equipments and tools are invented in order to automate numerous industrial activities; such as cutting, drilling, milling, threading, shaping etc. A small or large work piece made from wood, metal etc. can be used to create the required product using a shaping tools. It is basically utilized to shape straight and flat metal surfaces.

Today, several types of machines, equipments and tools are invented in order to automate numerous industrial activities; such as cutting, drilling, milling, threading, shaping etc. A small or large work piece made from wood, metal etc. can be used to create the required product using a shaping tools. It is basically utilized to shape straight and flat metal surfaces. A versatile lathe is a tool that turns metal materials to shave away the exterior part and form the desired shape. A metal stock is mounted on a lathe that spins the material like a potter’s wheel. The turning work piece is pressed against a sharp cutting tool to create a precisely shaped material.

A versatile lathe is a tool that turns metal materials to shave away the exterior part and form the desired shape. A metal stock is mounted on a lathe that spins the material like a potter’s wheel. The turning work piece is pressed against a sharp cutting tool to create a precisely shaped material. A machine press refers to several multi-purpose metal cutting tools. They are primarily used to cut and deform metals by pressing the work piece in between two heavy plates. The machine can cut, bend, stamp and shape metal sheets into different forms; depending on the shape of the pressing plates. A typical press may be bench or floor mounted; and is usually powered by pneumatic force or electricity.

A machine press refers to several multi-purpose metal cutting tools. They are primarily used to cut and deform metals by pressing the work piece in between two heavy plates. The machine can cut, bend, stamp and shape metal sheets into different forms; depending on the shape of the pressing plates. A typical press may be bench or floor mounted; and is usually powered by pneumatic force or electricity.

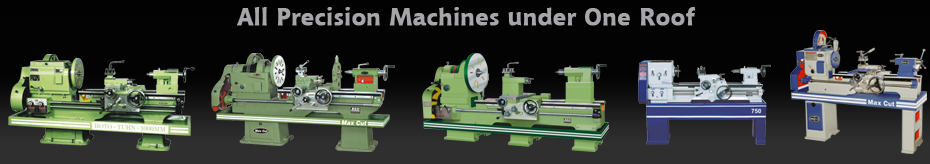

The lathe is a multipurpose machine tool; that rapidly rotates the work piece along its axis to perform various tasks like cutting, shaping, drilling, turning, sanding etc.; in order to create a symmetrical object. Nowadays, the latest manufacturing machines use computers to automate numerous manual functions in several industrial segments; including lathe machine operations.

The lathe is a multipurpose machine tool; that rapidly rotates the work piece along its axis to perform various tasks like cutting, shaping, drilling, turning, sanding etc.; in order to create a symmetrical object. Nowadays, the latest manufacturing machines use computers to automate numerous manual functions in several industrial segments; including lathe machine operations. drills. The same result may otherwise be difficult or impossible, while using the conventional lathes. This CNC machine also incorporate tool holders and coolant pumps to reduce deterioration. CNC lathe machines have the ability to cut curved contours without using special shaping tools. This is possible due to the computer programmed and controlled speed of the two motion axes and the spindle simultaneously.

drills. The same result may otherwise be difficult or impossible, while using the conventional lathes. This CNC machine also incorporate tool holders and coolant pumps to reduce deterioration. CNC lathe machines have the ability to cut curved contours without using special shaping tools. This is possible due to the computer programmed and controlled speed of the two motion axes and the spindle simultaneously. A CNC lathe machine must be provided the relevant instructions to produce a new or different shaped object. This is done by a computer programmer, who prepares a set of machining instructions related to that process. It is then translates into a computer aided-automated manufacturing (CAM) program; for the particular machine to understand and operate accordingly. Then a CNC lathe operator in a machine shop or tool room will download the CAM program, set up the lathe; and then start the machine and intermittently monitor it until the process is completed.

A CNC lathe machine must be provided the relevant instructions to produce a new or different shaped object. This is done by a computer programmer, who prepares a set of machining instructions related to that process. It is then translates into a computer aided-automated manufacturing (CAM) program; for the particular machine to understand and operate accordingly. Then a CNC lathe operator in a machine shop or tool room will download the CAM program, set up the lathe; and then start the machine and intermittently monitor it until the process is completed.

We present variety of tools used in various standard and critical industrial applications. Some of the widely used industrial equipments are lathe, drill, tool room, sheet metal, shearing, press brakes, SPM & heavy, wood working and automobile unit. We are having expertise in manufacturing all types of industrial machines, which work accurately with high performance. These are made up of high quality sturdy materials to give a long life with low maintenance cost. Our wide ranges of lathe devices are demanded worldwide for perfection of work, quite affordable low cost for long durability.

We present variety of tools used in various standard and critical industrial applications. Some of the widely used industrial equipments are lathe, drill, tool room, sheet metal, shearing, press brakes, SPM & heavy, wood working and automobile unit. We are having expertise in manufacturing all types of industrial machines, which work accurately with high performance. These are made up of high quality sturdy materials to give a long life with low maintenance cost. Our wide ranges of lathe devices are demanded worldwide for perfection of work, quite affordable low cost for long durability.

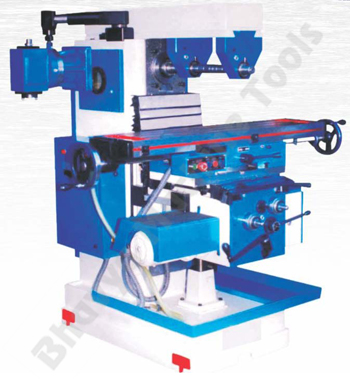

A milling machine is a versatile tool room machine which is used to remove undesirable metal from the sheet metal to give a specific shape to an object. The first milling machine was invented by Eli Whitney for producing interchangeable Musket Parts. After that, there were many developments brought in a milling machine which has made it a special kind of tool room machines. Due to these developments, the metal can be removed now with more speed and accuracy. The developments brought in versatile features in a milling machine as so now a milling machine can not only perform metal cutting but it can also used for boring, slotting, circular milling dividing, and drilling. Different types of milling machines were developed with versatile features which are briefed below:-

A milling machine is a versatile tool room machine which is used to remove undesirable metal from the sheet metal to give a specific shape to an object. The first milling machine was invented by Eli Whitney for producing interchangeable Musket Parts. After that, there were many developments brought in a milling machine which has made it a special kind of tool room machines. Due to these developments, the metal can be removed now with more speed and accuracy. The developments brought in versatile features in a milling machine as so now a milling machine can not only perform metal cutting but it can also used for boring, slotting, circular milling dividing, and drilling. Different types of milling machines were developed with versatile features which are briefed below:-