Sheet metal machines are used for shaping, cutting, pressing, forming etc. metal sheets into various shapes and sizes. Different types of sheet metal units are available in the market. There are different for different jobs to be carried out.

Before buying the sheet metal it is good to survey the market for the right product. Check on the internet for different products available online, the cost and the feedback of people using the products of different companies, brands and the type of equipment. Check for good deals being offered. Be very sure about your specific requirements.

Points to consider while buying a Sheet Metal Machine:

If you want to buy a new tools then buy from a reputed and genuine manufacturing company.

Take advice from people who are using sheet metals as they will have more experience and the knowledge regarding the equipments.

Consider Customer Support and Maintenance Services

When purchasing sheet metal machines, consider the level of customer support offered by the manufacturer or dealer. A good manufacturer will provide comprehensive customer service, including installation support, troubleshooting, and maintenance. Check if the manufacturer offers after-sales services like machine servicing, availability of spare parts, and response times for repairs.

It’s important to understand that regular maintenance is critical for keeping your sheet metal machine in optimal condition. Ask the manufacturer or seller about routine maintenance schedules and the availability of service technicians in your area. A machine that’s easy to maintain will save you a lot of money in the long run and ensure a longer operational lifespan.

Check for Machine Features: Safety and Integration

Safety should always be a priority when selecting a sheet metal machine. Look for machines that meet international safety standards and include built-in safety features like emergency stop buttons, automatic shut-off functions, and protective shields around moving parts. A machine with certifications like CE or ISO ensures that the product has been tested for safety and compliance with industry standards.

Furthermore, check whether the sheet metal machine can easily integrate with your existing equipment or systems. This is particularly important if you have a production line or a factory setup that already includes other machinery. An easily integrable machine can save you time, effort, and money when making future upgrades or modifications.

Identify the type of device you want and set the budget limit. Your budget limit is the final amount you are ready to spend to buy.

Online shopping is a good idea as you can compare more variety of sheet metals. You can compare the specifications of different models and select the one that suits your requirements the most. All the information about the equipments is available on the net.

People offer discounts on the tools being resold. You can get them at very cheap rates. Some online stores also sell used sheet metals. Make sure the machines available are in good working condition and these are being sold at a rational price.

Compare the cost of different models available, the availability of the model you wish to buy and the time taken to deliver.

Don’t get tempted by companies selling tools at low cost. These may not be in good working condition and you may end shelling out more money to get it repaired.

Most important point to consider is the warranty period the manufacturer is offering and also the after sales service available. Inquire about the kind of service the dealer provides and find out other customers’ views.

It must be durable, long lasting and strong.

Energy Efficiency and Environmental Impact

Another important aspect to keep in mind when buying a sheet metal machine is its energy efficiency. Machines that are designed to use less power not only reduce operational costs but also have a lower environmental impact. Check the energy ratings of the machines, as high-efficiency motors and components consume less energy, leading to lower energy bills over time. Machines with lower carbon footprints align with sustainable practices and can be a selling point for eco-conscious businesses.

If the device is compact and energy efficient it will consume less energy so the operational cost will be less.

It should be versatile and easy to use. You can then perform a number of operations on one machine.

The design should be such that the motor does not hinder the work. Also check the noise level and the amount of vibrations produced.

Examine the Technology and Automation Level

In today’s fast-paced industrial world, automation is an important factor in choosing sheet metal machines. Machines equipped with advanced technology, such as digital controls, automated feed systems, or robotic arms, can significantly improve operational efficiency. Consider whether you need fully automated systems or semi-automated machines depending on your production needs. A higher degree of automation can reduce the need for manual labor, increase throughput, and reduce human error in the production process.

You should also look at the user interface and the level of technology embedded in the machine. Is it equipped with touchscreen controls? Does it offer real-time diagnostics and data collection? Modern machines may offer these advanced features, allowing operators to monitor performance and adjust settings with ease. Such technology can drastically improve the workflow and make the machine easier to operate.

Space and Placement Considerations

When buying sheet metal machines, space is often overlooked but plays a crucial role in the long-term viability of the machine. Make sure the machine you choose will fit in your existing workspace without overcrowding. Consider the floor space required for the machine and any accessories such as workstations, conveyors, or material storage. Also, check the machine’s mobility-whether it is easy to move if necessary, and if it includes any wheel kits or can be easily relocated without major adjustments.

The manufacturer must provide you with an instruction manual that is easy to follow and that explains how to install, and use it.

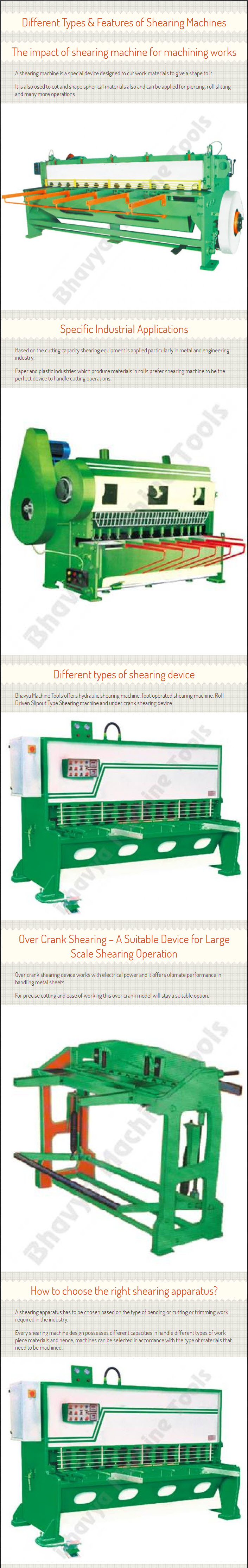

Read more in detail for Sheet Metal Machines.

Conclusion

It is always better to buy equipment of a superior quality, even if it is a little costly, but it is more dependable, useful and will last longer. Spend time to collect as much information as possible about the machine before you buy a sheet metal. Select your tools with care to make sure they offer maximum usability.

Understanding Return on Investment (ROI) and Future-Proofing

Purchasing a sheet metal machine is a long-term investment, and evaluating the return on investment (ROI) is crucial. Assess how the machine will impact productivity, operational efficiency, and cost savings. If the machine is capable of handling high-volume operations or improving accuracy, the ROI can be significant over time.

It’s also important to think about future-proofing. Technology is constantly evolving, so consider machines that offer upgradeability or modular components. Machines with features that allow for easy upgrades can save you money in the future, especially if you need to keep up with growing business demands.

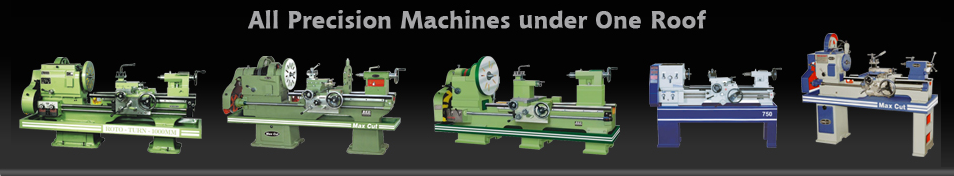

The lathe is one of the most essential tools. It is used for numerous purposes such as boring, cutting, drilling, grinding, grooving, knurling, parting, polishing, reaming, threading, turning, etc. Actually, this versatile equipment helps to manufacture precise products made from various materials like metal, plastic, wood, etc. A device can hold and turn different types of objects against a cutting tool for producing the required item. Today, advanced technology has helped to design and provide a wide range of equipments throughout the world. This includes the popular variants of v-belt drive lathe namely light, medium, and heavy duty. Each of these is crafted to execute a specific task in the workshop.

The lathe is one of the most essential tools. It is used for numerous purposes such as boring, cutting, drilling, grinding, grooving, knurling, parting, polishing, reaming, threading, turning, etc. Actually, this versatile equipment helps to manufacture precise products made from various materials like metal, plastic, wood, etc. A device can hold and turn different types of objects against a cutting tool for producing the required item. Today, advanced technology has helped to design and provide a wide range of equipments throughout the world. This includes the popular variants of v-belt drive lathe namely light, medium, and heavy duty. Each of these is crafted to execute a specific task in the workshop. The

The ![Lathe Machine - Types & Applications of Lathe Machines [INFOGRAPH] Lathe Machine - Types & Applications of Lathe Machines [INFOGRAPH]](https://machinetools.bhavyamachinetools.com/wp-content/uploads/2013/07/bhavya-july1.jpeg)

The power press is an important machine tool which is used to change the shape of a workpiece. In the ancient times metal was shaped manually using a hand hammer. Later on big hammers were used to press large quantities of metal at a time, or to press thick metal pieces. A helper was specially required to swing the sledge hammer while the smith positioned the workpiece. Thereafter steam power and wind mills were utilized to operate the large steam hammers. Later on due to electrification, most of the power presses now use electrical power or hydraulic power to obtain the required pressure. At the same time various types of dies were also discovered for use within it. Moreover, advanced methods and highly accurate equipments were also invented. Today these are mainly categorized based on their mechanism such as mechanical and hydraulic.

The power press is an important machine tool which is used to change the shape of a workpiece. In the ancient times metal was shaped manually using a hand hammer. Later on big hammers were used to press large quantities of metal at a time, or to press thick metal pieces. A helper was specially required to swing the sledge hammer while the smith positioned the workpiece. Thereafter steam power and wind mills were utilized to operate the large steam hammers. Later on due to electrification, most of the power presses now use electrical power or hydraulic power to obtain the required pressure. At the same time various types of dies were also discovered for use within it. Moreover, advanced methods and highly accurate equipments were also invented. Today these are mainly categorized based on their mechanism such as mechanical and hydraulic. These days, these are driven by a mechanical force or a hydraulic system. The power system or the source of these power presses may be an electric motor or an engine. The mechanical power press may utilize several types of drive mechanisms such as the crankshaft, eccentric, knuckle joint, etc. These drives help to transform the rotational movement of the motor into a linear movement of the ram. A fly wheel is also used to energize the machine. These presses have drives that are capable to provide a large force at the end of the strokes; hence they are useful for various punching and stamping operations. Further, it utilize a large piston and cylinder for driving the ram. This system has the ability to provide longer ram strokes as compared to the mechanical machine. Although it works relatively slower, they can continuously apply the required load. These presses may have various types of movements, depending on the number of slides operated independently.

These days, these are driven by a mechanical force or a hydraulic system. The power system or the source of these power presses may be an electric motor or an engine. The mechanical power press may utilize several types of drive mechanisms such as the crankshaft, eccentric, knuckle joint, etc. These drives help to transform the rotational movement of the motor into a linear movement of the ram. A fly wheel is also used to energize the machine. These presses have drives that are capable to provide a large force at the end of the strokes; hence they are useful for various punching and stamping operations. Further, it utilize a large piston and cylinder for driving the ram. This system has the ability to provide longer ram strokes as compared to the mechanical machine. Although it works relatively slower, they can continuously apply the required load. These presses may have various types of movements, depending on the number of slides operated independently.